Peek a bee!

About Project

Apiculture, commonly known as beekeeping is a practice where bee colonies are perpetuated in man-made hives. The process is intimately entwined with nature.

Every bee colony has a queen and it is the proverbial glue that holds the hive together. Sometimes a colony loses the queen and to sustain the hive a new queen is required to take over. In this impasse, the beekeeper introduces a new queen through a bee catcher and waits. If the colony accepts the queen, the queen is released into the colony and otherwise stays secured in the catcher. This queen bee catcher we designed facilitates this while ensuring a pleasant experience for the human as well as the bee.

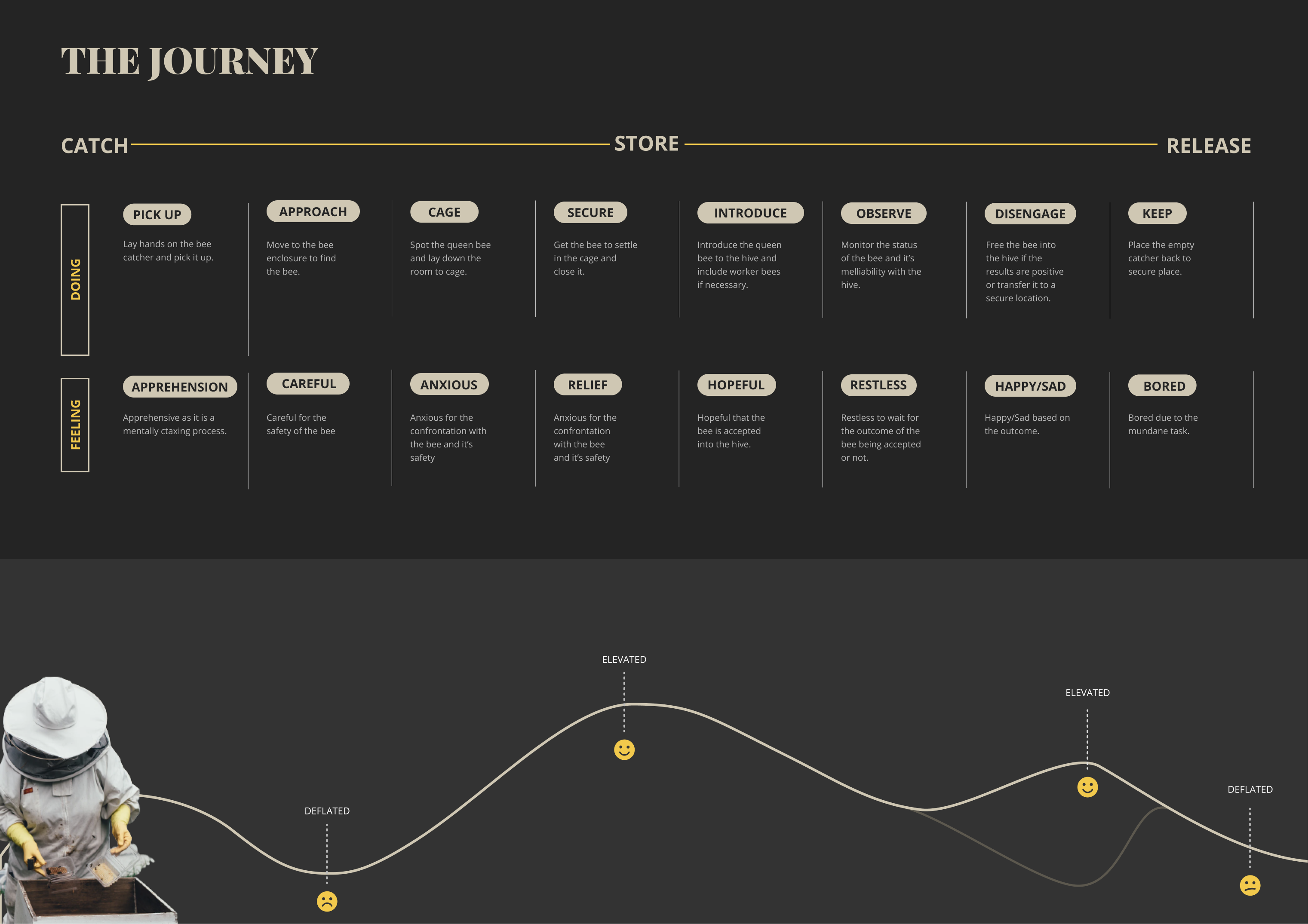

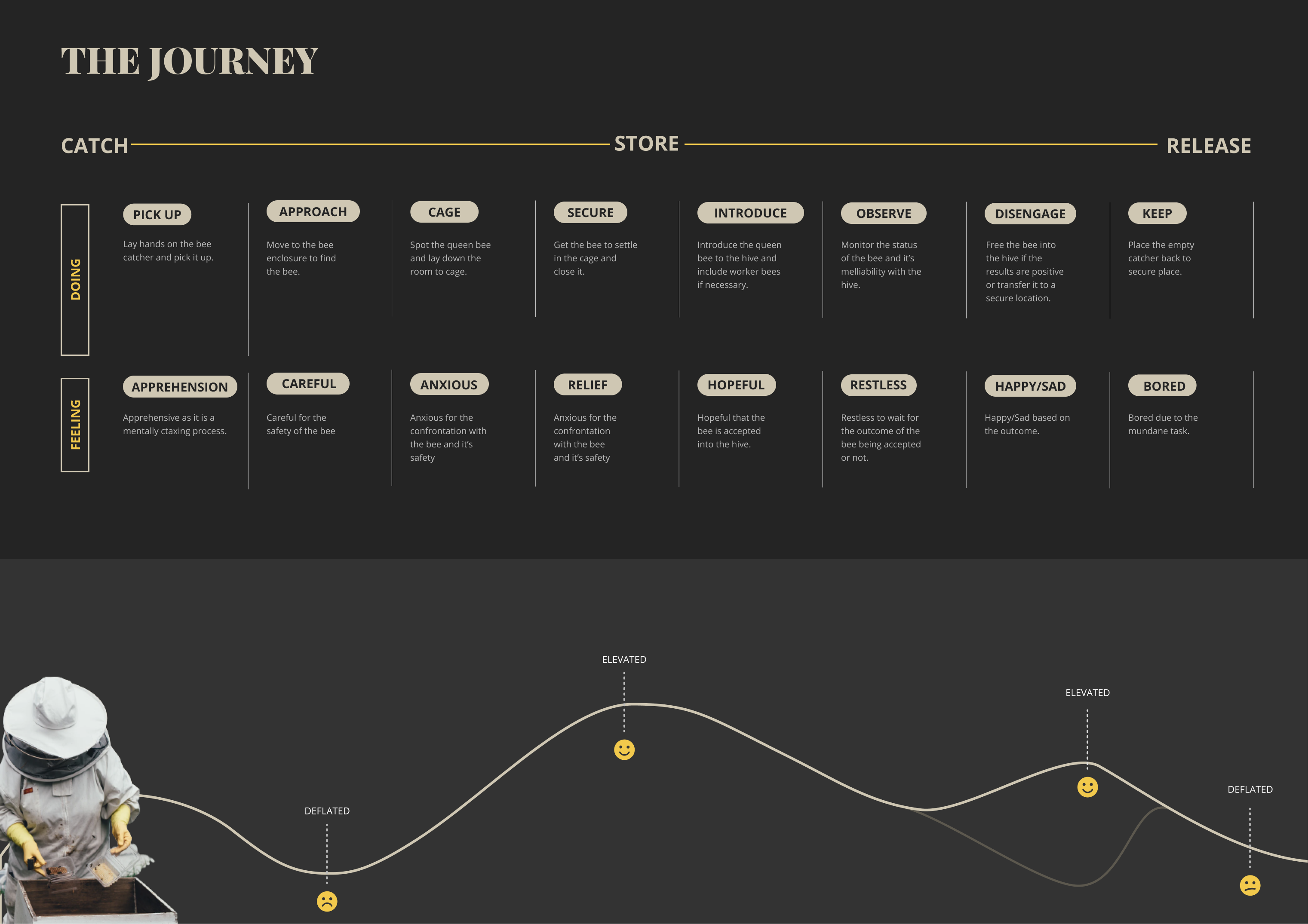

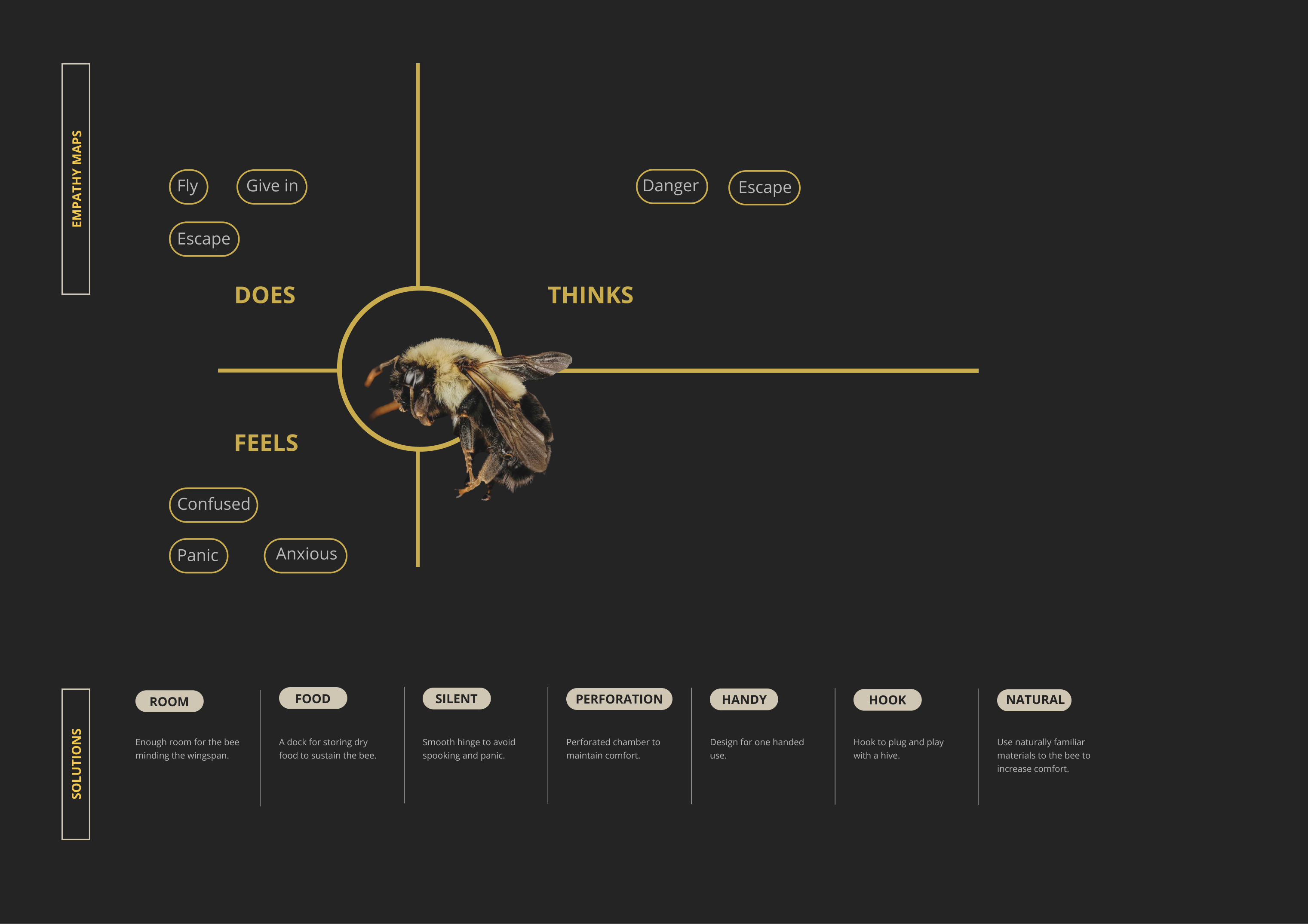

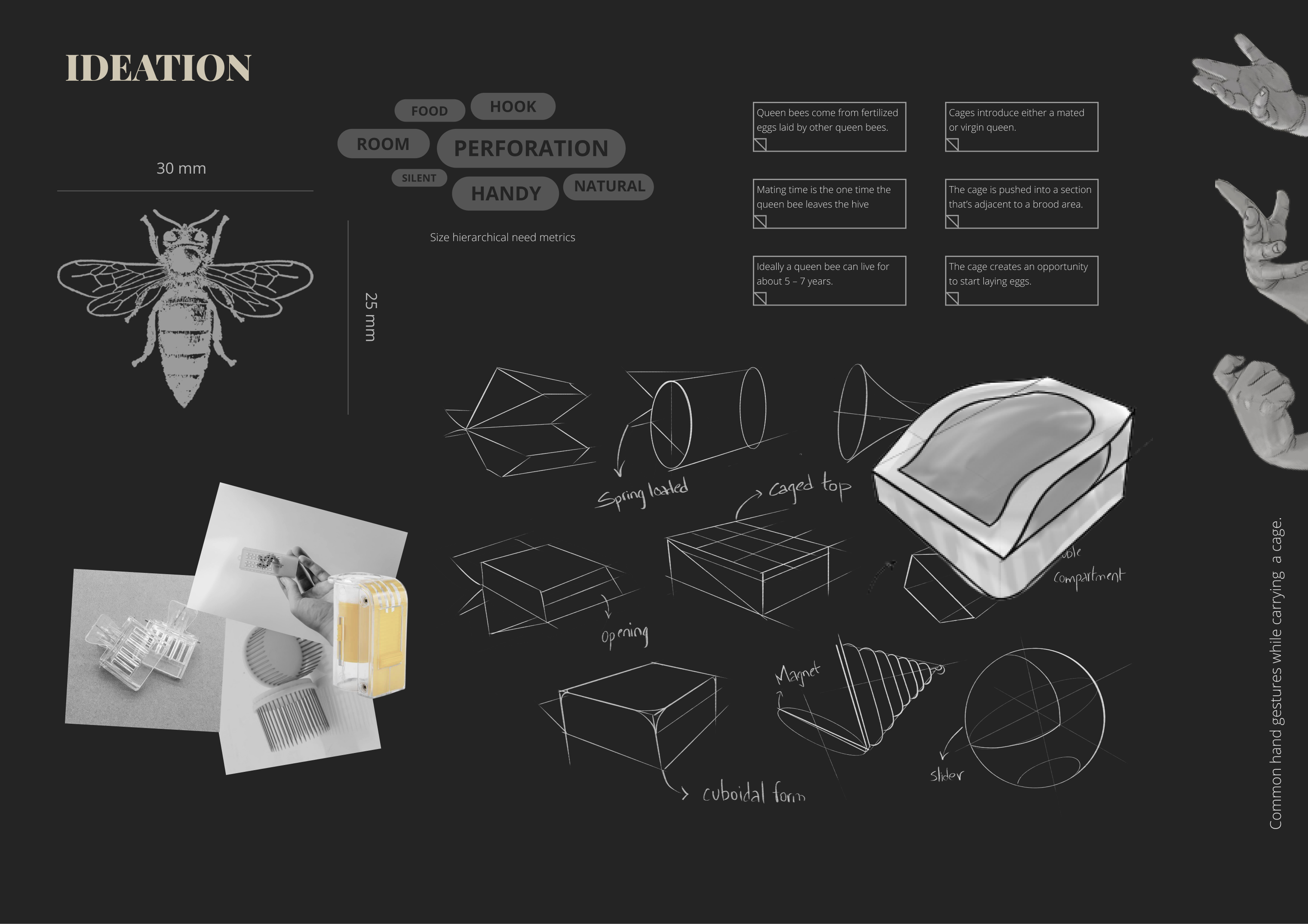

We began by mapping out the journey of the bee and the beekeeper to address the pain points that helped generate actionable solutions.

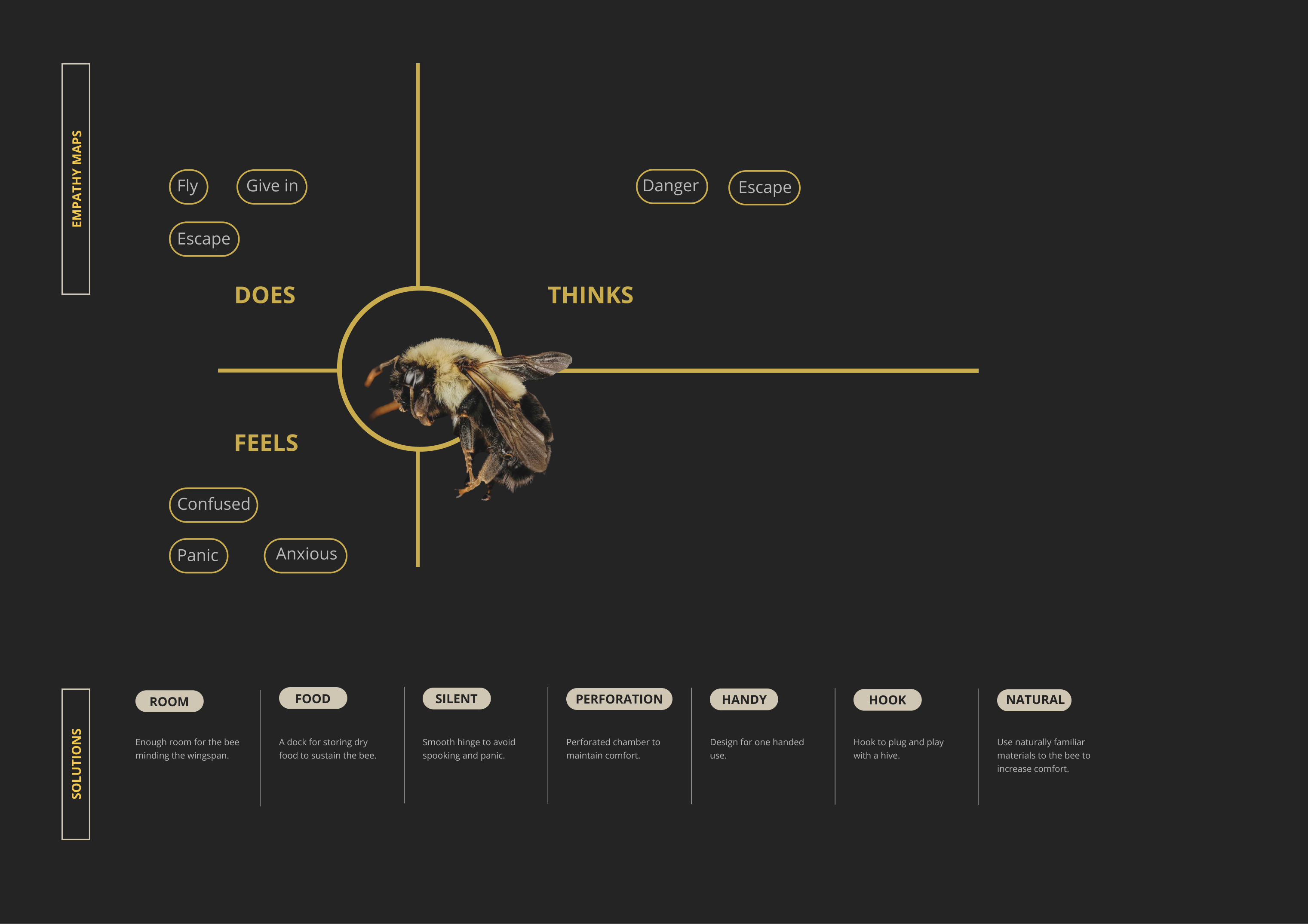

The actionable points were:

– Enough room for the bee minding the wingspan.

– A dock for storing dry food to sustain the bee.

– Smooth hinge to avoid spooking and panic.

– Perforated chamber to maintain comfort.

– Design for one handed use.

– Hook to plug and play with a hive.

– Use naturally familiar materials to the bee to increase comfort.

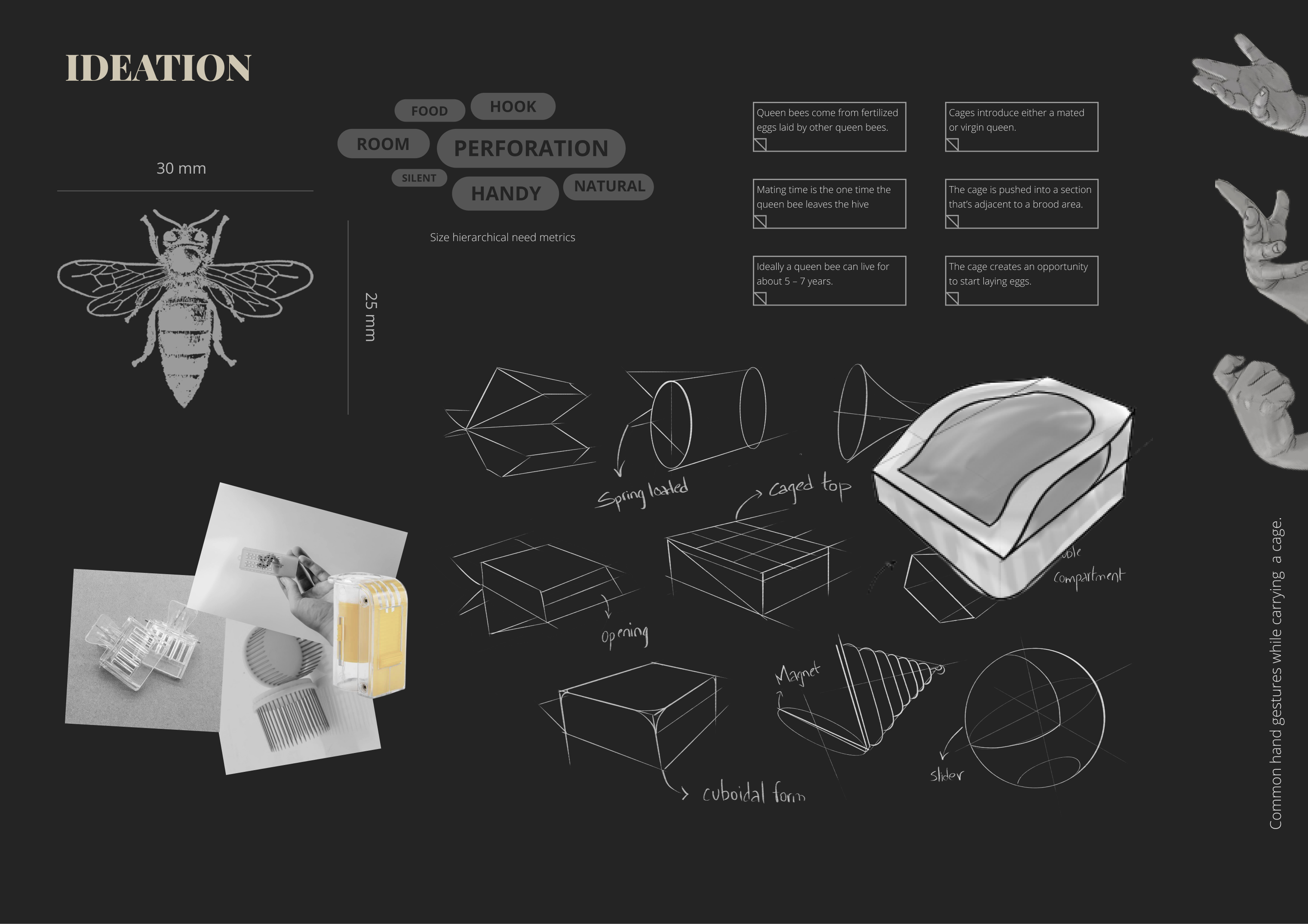

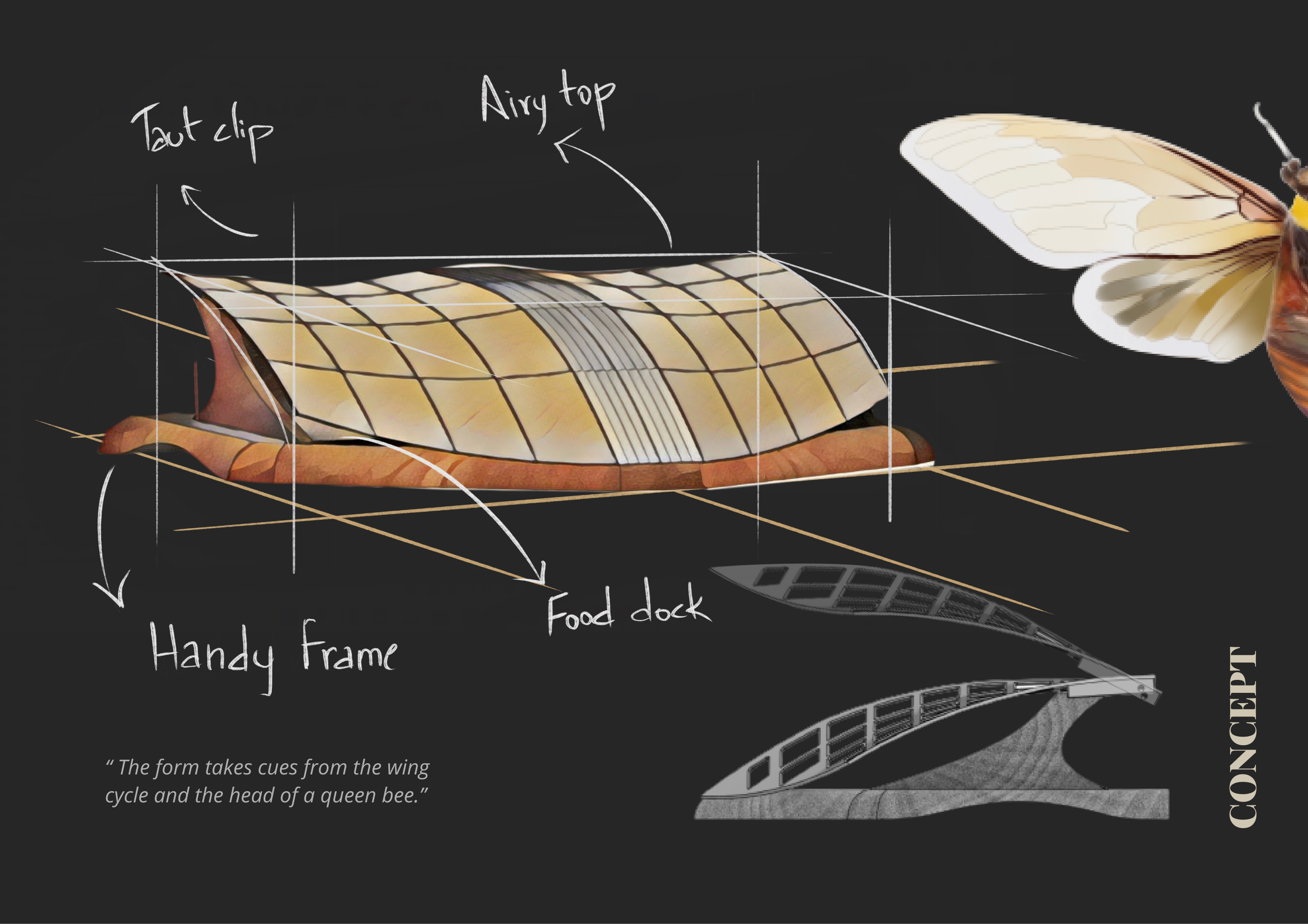

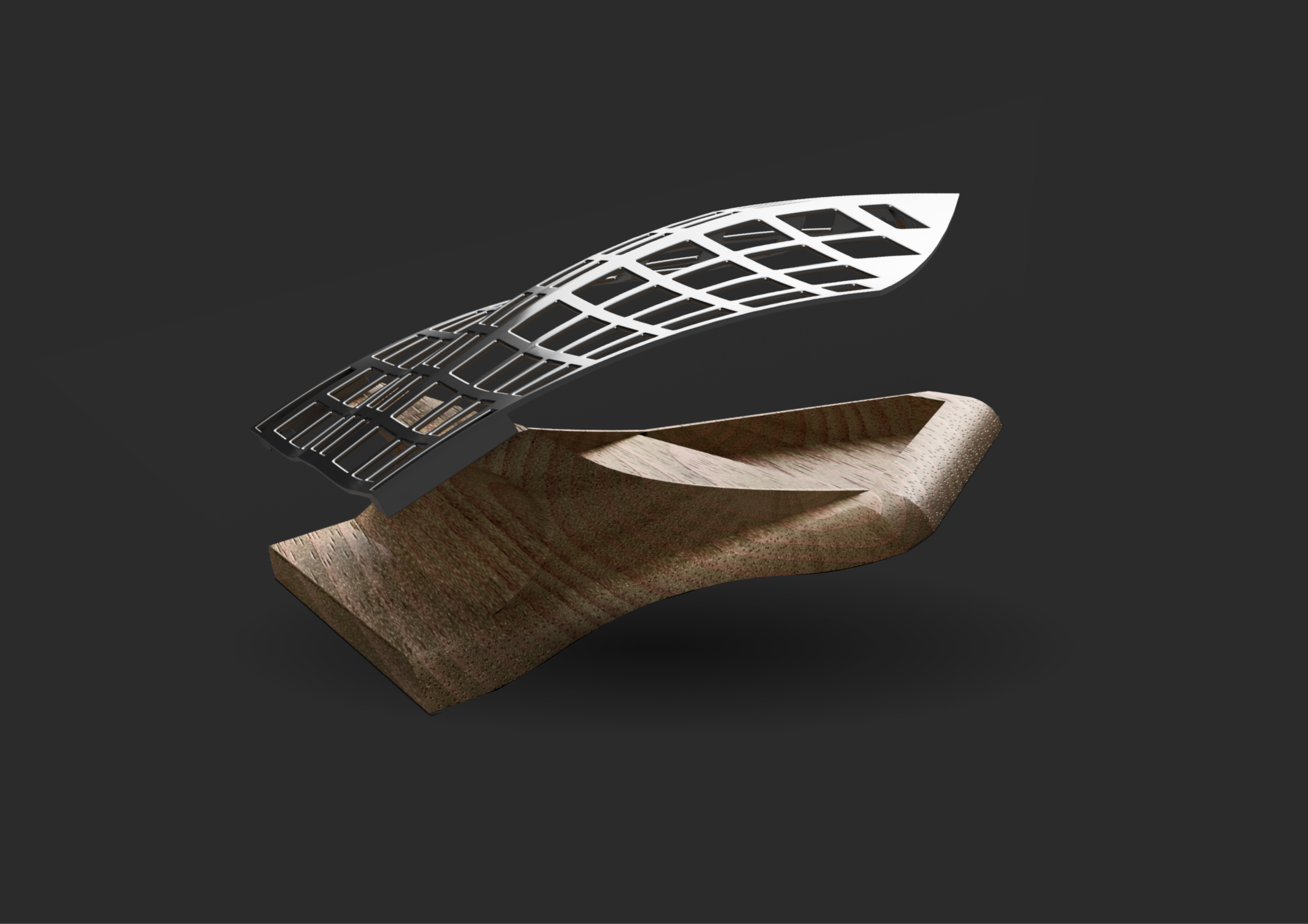

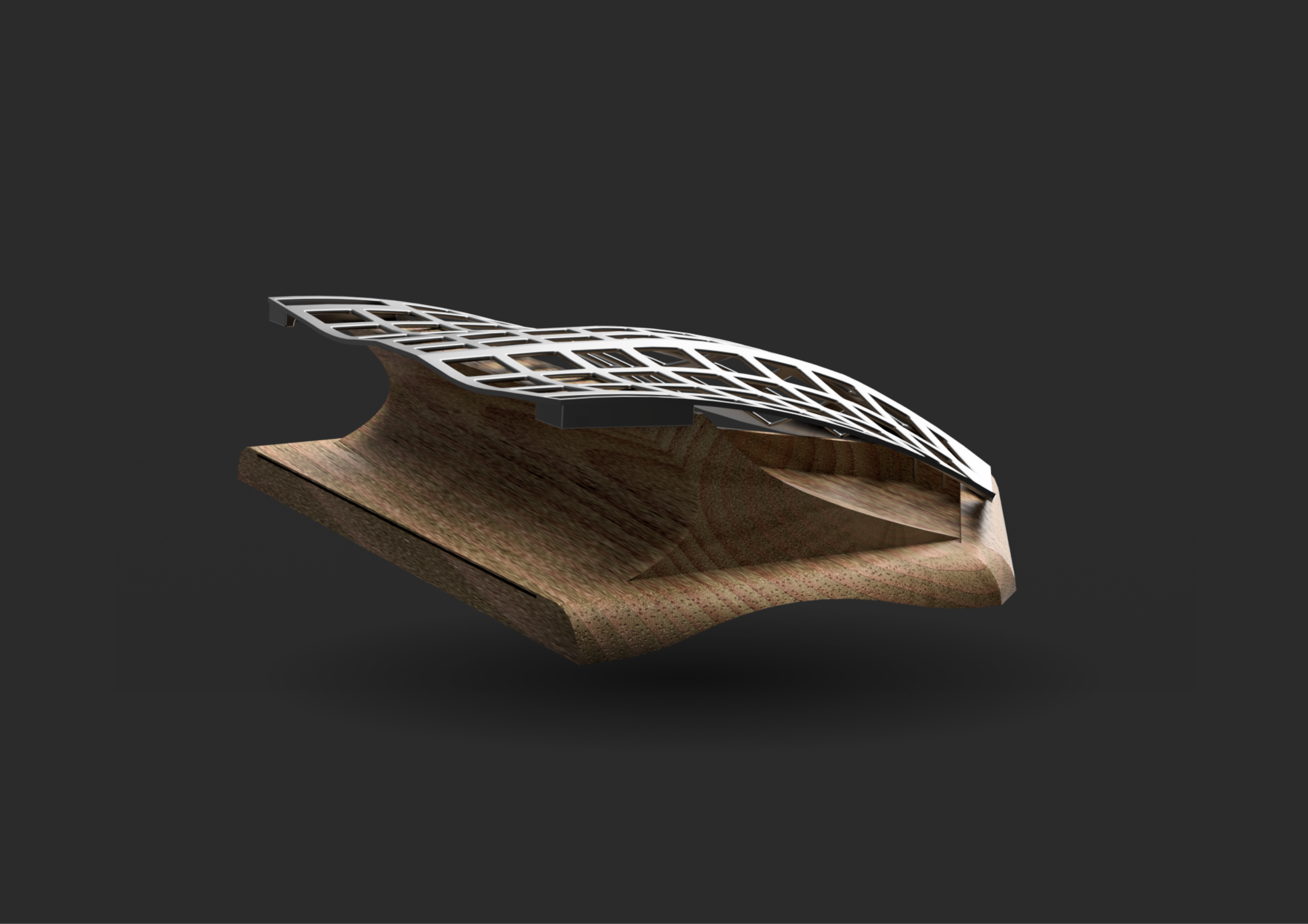

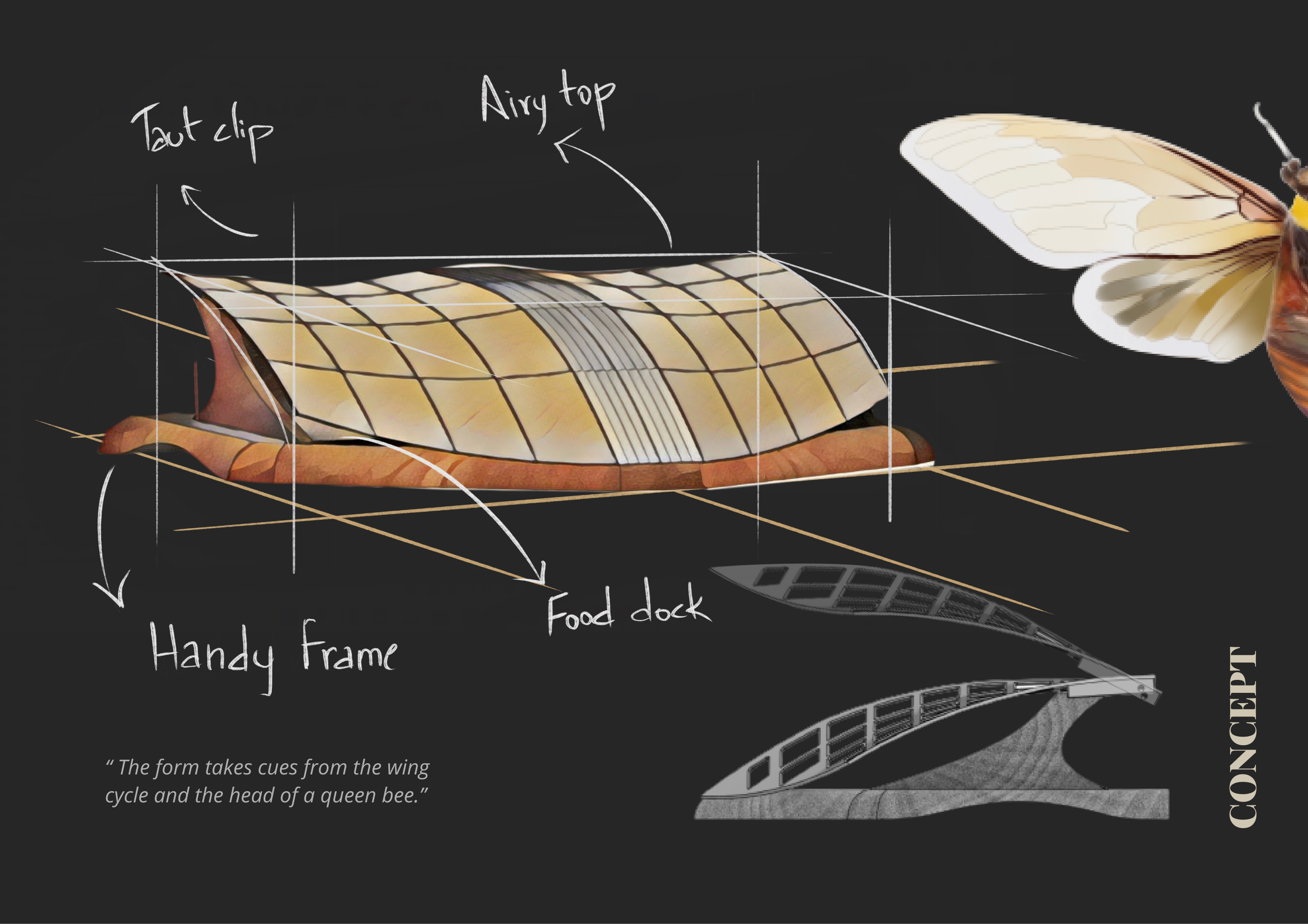

With the list of solutions we began ideating and digging deep into the process to generate a volume of iterations. We then proceeded to evaluate each iteration against the solutions it addressed using a weighted scale and landed on a defined direction. We then proceeded to fine tune the form taking inspiration from the bee’s wings that flow incandescently.

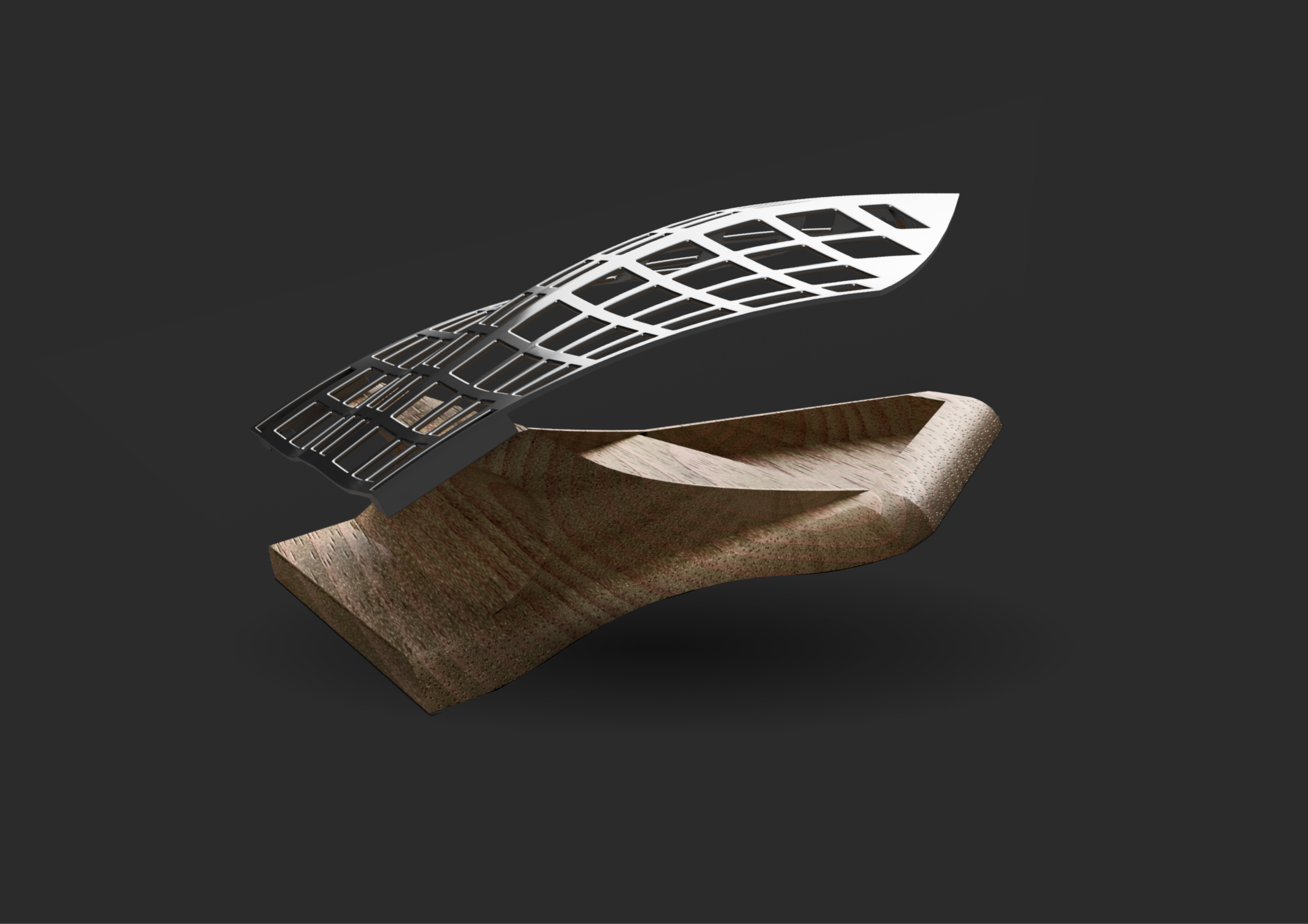

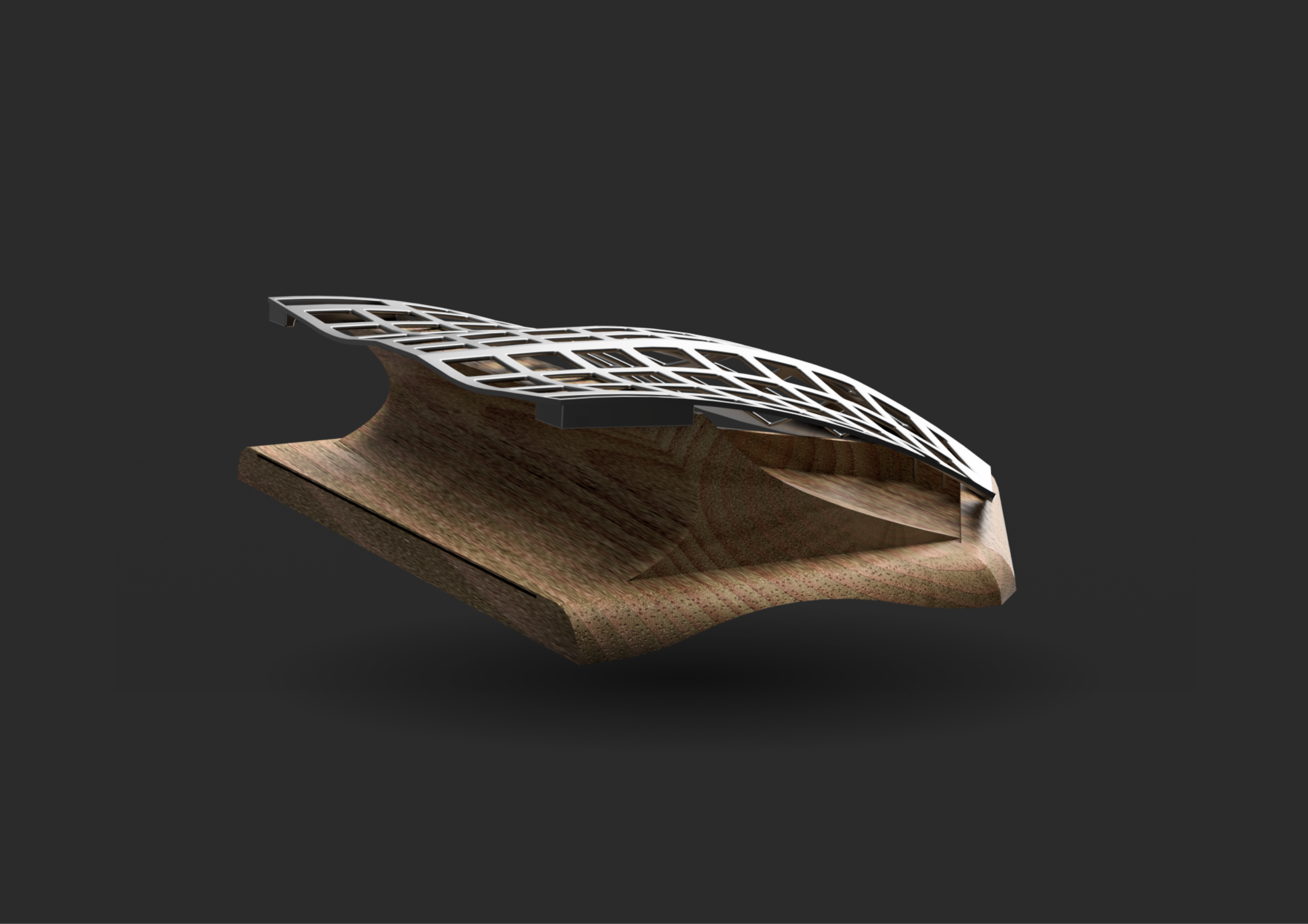

We then proceeded to do the material exploration using cradle to cradle method and landed on titanium, stainless-steel and pine wood for three distinct components:

– Cage.

– Torsion spring.

– Base structure.

We proceeded to set specific dimensions based on the anatomy of the bee and the anthropometry of the human hand and generated all the technical assets to move on to the next stage i.e. prototyping.

– The cage can be manufactured by a CNC machine adopting a plasma cutting method that helps with high perforation speed.

– The standard 5mm torsion spring can directly be sourced or custom made from a b2b manufacturer.

– The initial base structure can be cut through an electrical saw and finished off manually by a woodworker.

This project forced us to look into a space where the interactions are so natural which was an exhilarating task and gave us perspective and newfound empathy towards beekeepers, the majestic bees and mother earth.

-

Bee catcher 1-f6fa778c

Bee catcher 2-6f4e804b

Mood board

Bee catcher 3-f5a487c1

User journey

Bee catcher 4-c42504d4

Bee journey & solutions

Bee catcher 5-1fb0ce54

Ideation

Bee catcher 6-a46e1d1b

Concept

Bee catcher 7-0ebdc894

Hi-fidelity render

Bee catcher 8-a5a19345

Hi-fidelity render

Bee catcher 9-85eb7fc7

Hi-fidelity render

Bee catcher 10-c738e26f

Technical specifications

Bee catcher 11-7cc457ff

Use case

Bee catcher 12-ad5f6ab6

Use case

Bee catcher 13-72611cbc

Use case - Sree Krishna, Shruti

- Product design: object | Eco project

-

A carefully crafted queen bee catcher for apiculture.

Designers/Architects

Sree Krishna, Shruti