Flip-Flop

About Project

When you bend a strip of plywood you get an elastic curve. What geometry does this curve follow? The interest in line and movement is expressed through a refined vocabulary, derived from the functional aspects of design. The main structural elements are strips of plywood that fold in a specific and supplementary manner, in line with proportions of the human body so as to establish chair’s dimensions.

Flexibility and transformation are the fundamental ideas behind this design. Chair can respond to user’s mood since it can be transformed just by flipping it. This results to 2 different seating postures and designs as per the user’s needs. Besides the alteration, this gives the product a visual consolidation emphasizing the reduction of materials and unification of forms.

Exploring the value of wooden manufacture and the flexible nature of wood as a construction material, chair is constructed of a series of plywood elements. Fluid linear forms establish a visual rhythm through the graphic lines of the design. This analytical construction logic with curves and crisp lines defines a characteristic profile with a light and elegant effect. Having as a principle the material restraint and purity of form, the design quality is based on geometric folds and lines which result in an interconnection of different parts that all service the function.

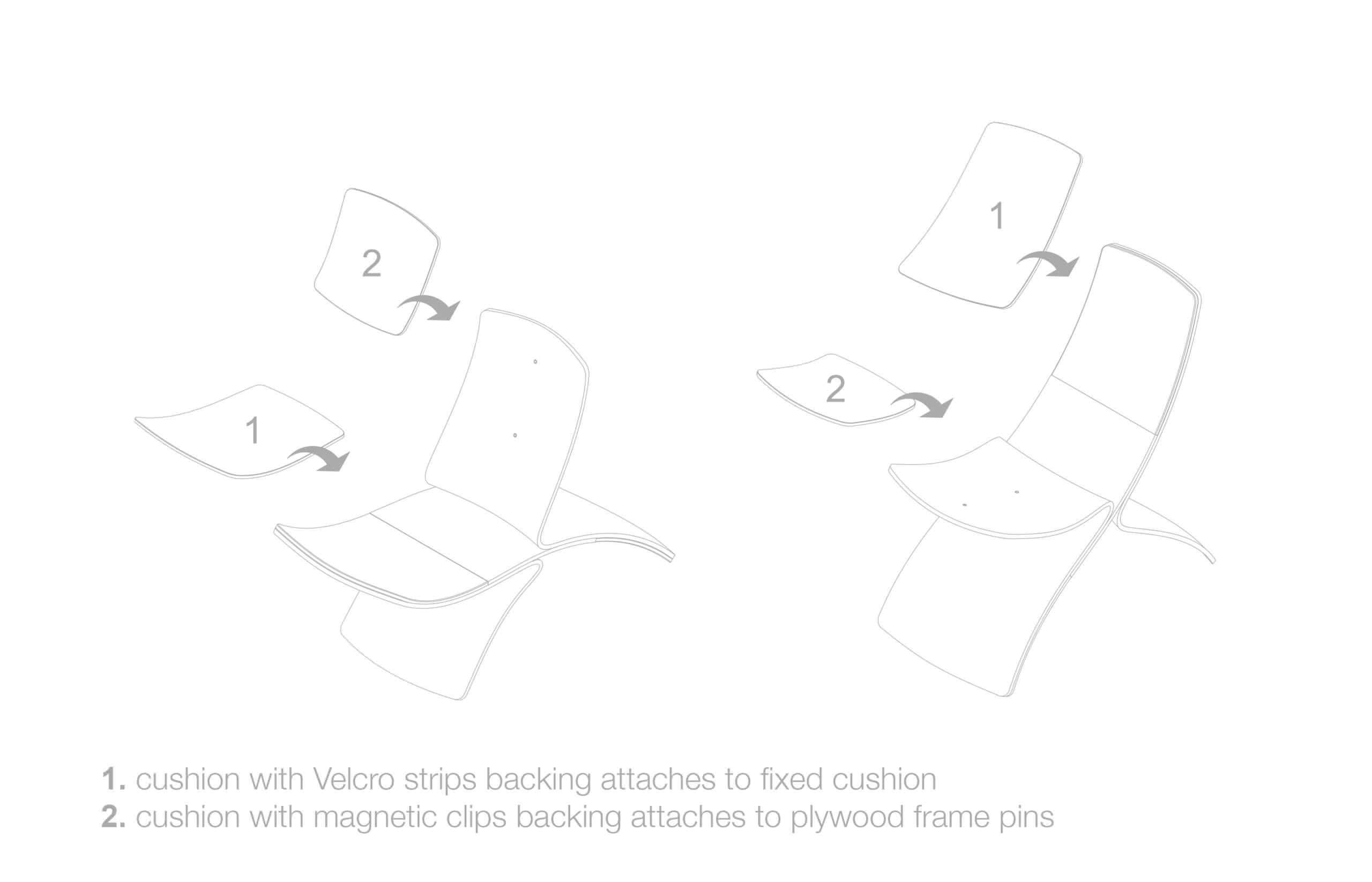

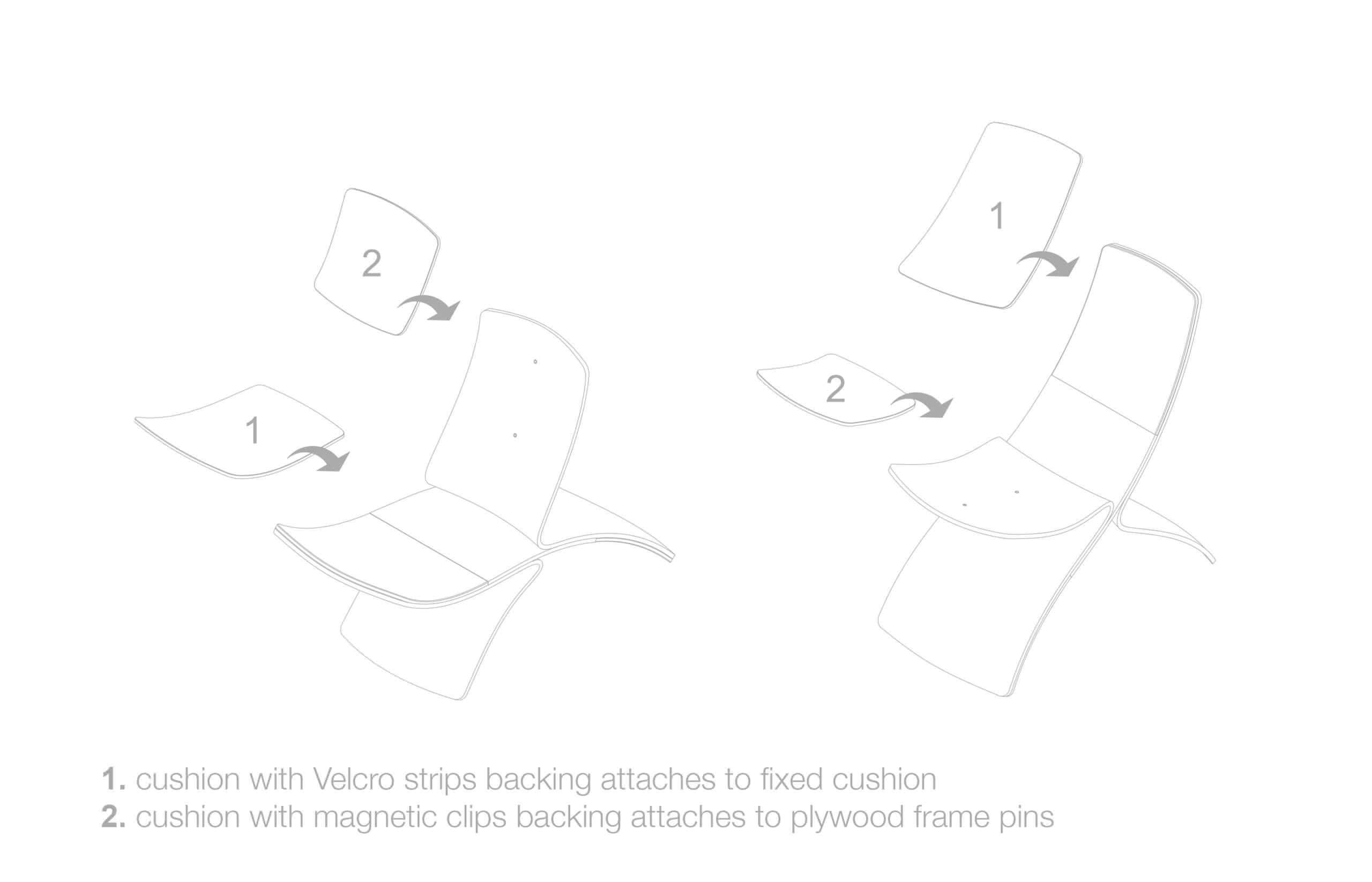

Structural stability is attained by the overlapping plywood strips that curve into one another and are glued on connection points. The curve segments are combined together taking into account physically satisfying posture as well as ergonomics. These provide the necessary flexibility that thin layers of plywood offer as a construction material, together with the cushions attached to them. Cushions are designed to act as an extension of the chair’s main framing, having as a basic principle the minimum use of material and minimum number of construction elements.

The manufacturing process used for the plywood is steam bending – a low energy, low waste process using no toxic glues, just water. The process of steaming the wood also seasons it at the same as it is bent, using a fraction of the energy required in conventional kiln drying. Plywood sheets are spray painted and varnished on all sides in natural beech wood finish and sleek black. With the fluidity of seat and the linearity if strips, design is suggestive of plant growth. In this way it expresses the spirit of the material it is made of.

-

1-3f8bff8a

2-dbee95bc

3-dac9a756

4-71df02a8

5-1cf937c8

6-57175b15 - Niko Kapa

- Studio Niko Kapa

- Furniture design: series

-

Chair can respond to user’s mood since it can be transformed just by flipping it. This results to 2 different seating postures and designs as per user’s needs.

Designers/Architects

Niko Kapa

Company

Studio Niko Kapa